Welcome to NEUMO

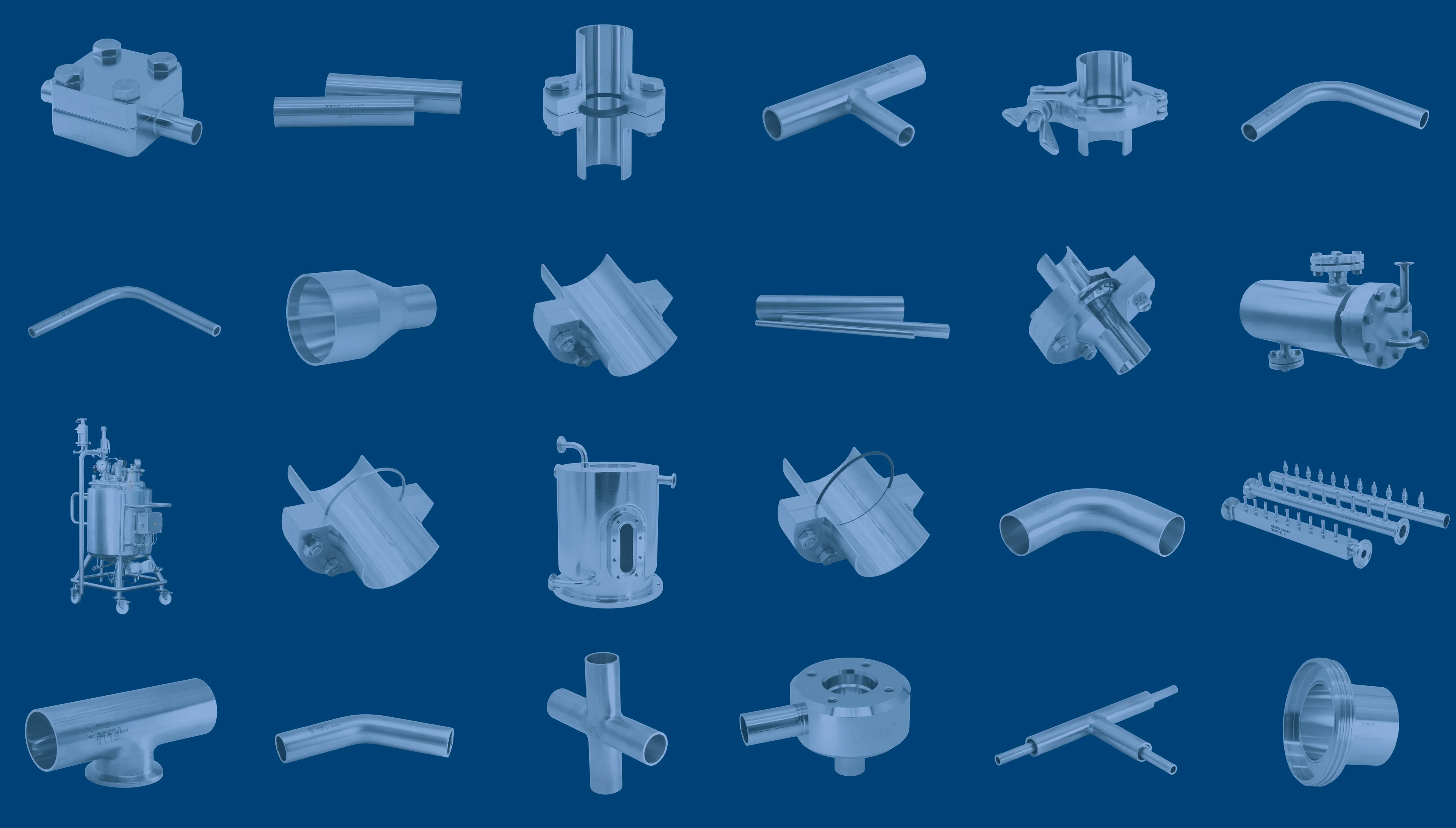

The NEUMO Ehrenberg Group is an owner-managed, globally active group of companies with over 2,300 employees worldwide. Founded in 1947, NEUMO laid the foundation for the future with the construction of the NEUMO Ehrenberg Campus, making a strong commitment to its headquarter in Knittlingen, Germany. In the coming years, this site will continue to grow through strategic investments and infrastructure expansion. As a technology leader in aseptic and sterile fluid handling, we develop, manufacture and supply stainless steel tubes and pipes, hygienic fittings, connectors, process vessels, valves, and heat exchangers, including products made from highly corrosion-resistant special alloys. These components are essential for the high-purity and hygienic process environments in the biotechnology, pharmaceutical, chemical, and food & beverage industries. Our expertise is underscored by a range of international patents in hygienic connection technology and weld-free assembly systems.

Pharma & Biotech

High-Purity Stainless Steel Solutions

As a global leader in high-purity process components, NEUMO supplies the pharmaceutical and biotech industries with premium stainless steel piping systems, hygienic fittings, and process vessels. Our solutions meet the strictest hygiene and quality standards and are trusted in critical applications worldwide. With over 20 years of expertise at our Knittlingen site, we actively shape the industry through participation in international committees such as ASME BPE and DIN, ensuring compliance, innovation, and future-proof design.

Semiconductors

SCiMax® Ultra-Clean Process Components

With our SCiMax® product line, developed in close cooperation with EGMO, we supply ultra-clean stainless steel components for the semiconductor industry. Guaranteed surface roughness (< 0.25 µm Ra), multi-stage cleaning, and cleanroom packaging ensure maximum purity, precision fit, and process reliability. Our portfolio includes electropolished tubes, double-jacketed COAX fittings, and high-purity UHP components for critical process environments.

Food & Beverage

Hygienic and Corrosion-Resistant Process Solutions

Since 1947, NEUMO has been a trusted partner to the food and beverage industry. Our roots lie in the dairy sector “Neue Molkereitechnik” shaped our name and vision. Today, we supply high-performance stainless steel components to global filling plants and food producers, especially for corrosive media like ketchup or mustard. We offer a wide range of high-alloy special materials, and with our group members AWH (tubes, fittings & valves) and RIEGER (hygienic & aseptic valve technology), we provide complete hygienic processing solutions from pipework to valve systems.

Cosmetics

Hygienic Stainless Steel Components for Sensitive Processes

The cosmetics industry requires maximum hygiene, precision, and process safety core strengths of NEUMO. We supply leading manufacturers with high-quality stainless steel tubes and components tailored for sensitive production environments. Our patented, elastomer-free ConnectS® fittings offer reliable solutions for powder handling and eliminate common sealing weak points ideal for high-purity, low-contamination applications.

The MaxPure® stainless steel product line is designed to meet the pharmaceutical industries production specifications.

SCiMax® Flow Equipment is specifically designed to meet the stringent standards and requirements of the semiconductor industry.

The MaxCore® alloy family, offered by the NEUMO Ehrenberg Group contains a wide range of special alloys.

What is Stainless Steel?

Stainless steel is an iron-based alloy with at least 10.5% chromium, which provides corrosion resistance. It may also include elements like nickel, molybdenum, and carbon to improve strength and durability. Based on composition, stainless steel is classified into five main types: Austenitic, Ferritic, Martensitic, Duplex, and Super Duplex.

Claus` Corner – Stainless Insights

Since 2007, Claus Qvist Jessen has been investigating corrosion causes and sharing knowledge to prevent future damage. As a true stainless expert, Claus supports customers and educates professionals worldwide. Discover his practical tips on stainless steel use, benefits, and common pitfalls.

NEUMO Ehrenberg Campus

A journey from a vision to an incredible milestone - for the future of NEUMO and the region.